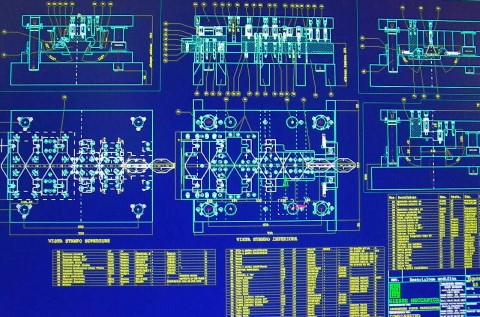

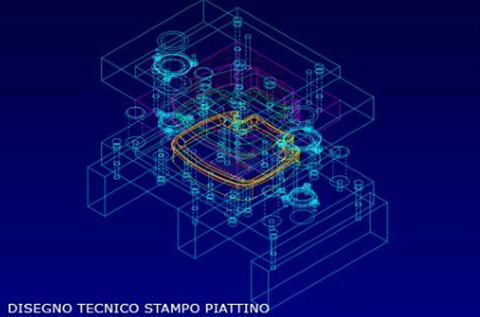

Planning

Thanks to a competent and consolidated technical office, constantly updated with new 3D programs, we are able to design:

- Molds for cold working of sheet metal, transfer, step, block and deep drawing;

- Molds for press and autoclave molding for the production of carbon fiber parts;

- Special mechanical, hydraulic and pneumatic equipment, engineering, customized technical solutions.

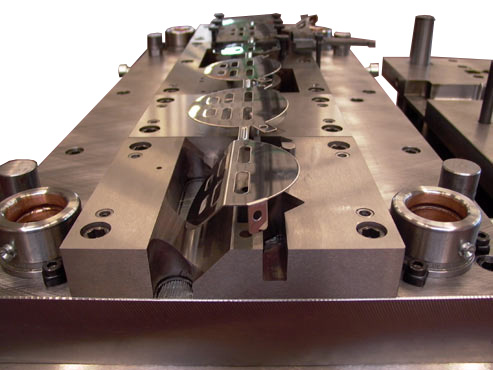

Sheet metal stamping and drawing dies

We design, develop and build block, step, progressive and deep drawing of small and large series for the molding of cold sheet metal parts.

The experience gained over the years has allowed us to produce molds in the following sectors: logistics, construction, roads, footwear, food, small parts, etc.

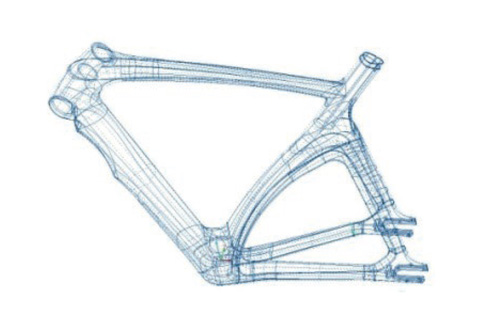

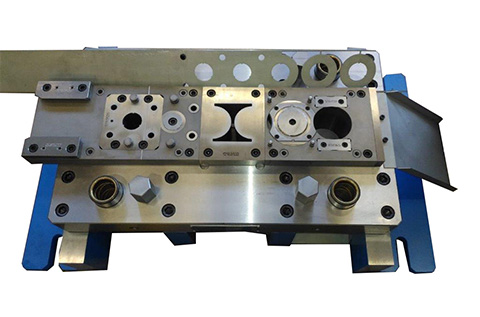

Carbon fiber molds

We design, develop and manufacture molds for press and autoclave molding, for the production of carbon fiber parts.

We also include among its customers important brands in the cycling sector for which we specialize in the design and manufacture of equipment and molds for the forming and molding of frames and parts in carbon fiber.

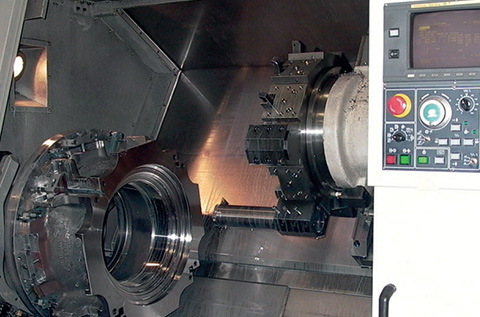

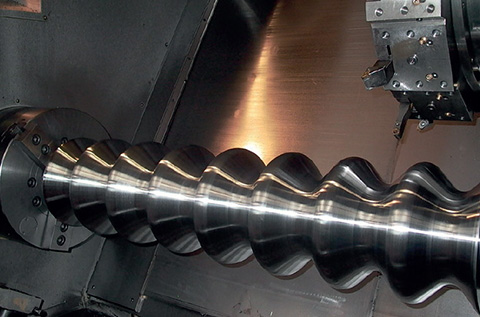

Mechanical processing and special equipment

We perform precision mechanical machining with CNC machines to customer specifications. Our machine park consists of:

- Milling machines max dimensions x2500 y800 z800;

- 5-axis machining centers;

- Wire EDM strokes x400 y300 z250;

- Drilling machine;

- Adjustments x1200 y600 z500;

- Lathes max diameter 900x1500;

- Measuring machines 1000x800x600;

- Presses up to 200T;

- punching;

- Bender.

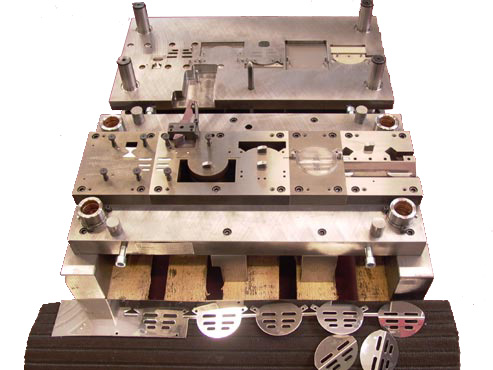

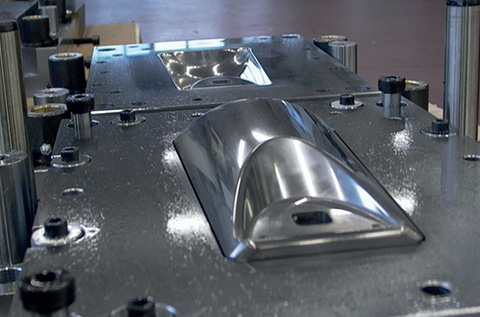

Printing and assembly

We carry out small and large series production of cold pressed sheet metal parts.

We also have an assembly department, to give the customer a finished product.

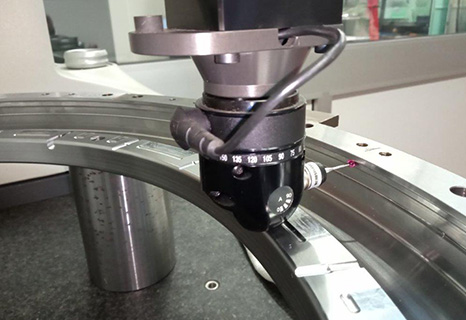

Quality check

We have an area equipped for quality control where the part is subjected to a series of careful checks.

The tools we put at your disposal are:

- Measuring machine for the control of finished pieces with CAD station for dimensional report and the detection of the geometries of the parts in 2D and 3D

- Roughness

- Durometer

- Comparator

- Calipers and micrometers

- Buffers